New The Art of Cleaning: How Understanding Chemistry Enhances Corporate Cleaning PracticesBlog Post

The Art of Cleaning: How Understanding Chemistry Enhances Corporate Cleaning Practices

Cleaning is often perceived as a straightforward task, but beneath the surface lies a complex interplay of chemistry and technique that can significantly impact the efficiency and effectiveness of cleaning processes in corporate environments. Drawing from the insights presented in Sean Kemper’s training guideline, "The Art of Cleaning: Understanding the Chemistry Behind the Clean," this blog explores how a deeper understanding of cleaning chemistry can transform how companies approach housekeeping. By delving into surfactants, emulsifiers, acids, alkalis, cleaning factors, product quality, dilutions, pH scales, and common housekeeping challenges like mold, floors, odors, glass, and blood, businesses can elevate their cleaning standards, improve workplace safety, and enhance operational efficiency.

The Science Behind Cleaning

At its core, cleaning is a chemical process. It involves the interaction of cleaning agents with soils, stains, and contaminants to break them down and remove them from surfaces. Understanding the chemistry behind cleaning products empowers companies to select the right tools and techniques for specific tasks, ensuring optimal results while minimizing waste and environmental impact.

Surfactants and Emulsifiers

Surfactants, or surface-active agents, are the workhorses of cleaning products. These compounds reduce the surface tension of water, allowing it to mix more effectively with oils and dirt. By lowering the energy required for water to penetrate and lift soils, surfactants make it easier to clean surfaces like countertops, floors, and equipment. In a corporate setting, where large areas need regular cleaning, surfactants ensure that cleaning solutions work efficiently, reducing the time and labor required.

Emulsifiers, a subset of surfactants, play a critical role in dealing with greasy or oily residues. They work by breaking down oils into smaller droplets that can be suspended in water, making it easier to rinse them away. For example, in office kitchens or industrial facilities where grease buildup is common, emulsifiers in degreasers ensure thorough cleaning without leaving sticky residues. Understanding how surfactants and emulsifiers function allows companies to choose products tailored to their specific cleaning needs, whether it’s tackling food spills in a cafeteria or oil stains in a manufacturing plant.

Acids and Alkalis

The pH scale, which measures the acidity or alkalinity of a substance, is a fundamental concept in cleaning chemistry. Acids (pH below 7) and alkalis (pH above 7) are used in cleaning products to target specific types of soils. Acidic cleaners, such as those containing vinegar or citric acid, are highly effective at removing mineral deposits like limescale or rust, which are common in restrooms or on metal surfaces in corporate facilities. Alkaline cleaners, such as those containing ammonia or sodium hydroxide, excel at breaking down organic soils like grease and protein-based stains, making them ideal for kitchen areas or high-traffic floors.

By understanding the pH properties of cleaning products, companies can match the right cleaner to the job. For instance, using an acidic cleaner on a greasy surface would be ineffective, while an alkaline cleaner could damage delicate surfaces like glass if not used properly. This knowledge helps businesses avoid costly mistakes and prolong the lifespan of their facilities.

The Five Cleaning Factors

Sean Kemper’s presentation highlights five key cleaning factors that influence the effectiveness of any cleaning process: chemical action, mechanical action, time, temperature, and concentration. These factors work together to ensure optimal cleaning outcomes.

Chemical Action: The choice of cleaning agent (e.g., surfactant-based, acidic, or alkaline) determines how effectively soils are broken down. Companies must select products that align with the type of soil they’re addressing, such as grease, mineral deposits, or organic matter.

Mechanical Action: This refers to the physical effort applied during cleaning, such as scrubbing or wiping. In corporate environments, tools like microfiber cloths, scrubbers, or pressure washers can enhance mechanical action, reducing reliance on harsh chemicals.

Time: Allowing cleaning solutions to dwell on surfaces increases their effectiveness. For example, letting a descaling agent sit on a bathroom sink for a few minutes can significantly improve its ability to remove limescale.

Temperature: Higher temperatures generally enhance cleaning by increasing the activity of chemical agents. However, companies must balance this with safety and material compatibility, as excessive heat can damage certain surfaces.

Concentration: The strength of a cleaning solution, determined by its dilution ratio, affects its efficacy. Over-diluting a product can render it ineffective, while using too high a concentration can be wasteful or damaging. Understanding proper dilution ratios is critical for cost-effective and safe cleaning.

By mastering these factors, companies can optimize their cleaning processes, reducing costs and improving results. For instance, a corporate office might train its janitorial staff to use the correct dilution ratios and dwell times for disinfectants, ensuring both cleanliness and safety.

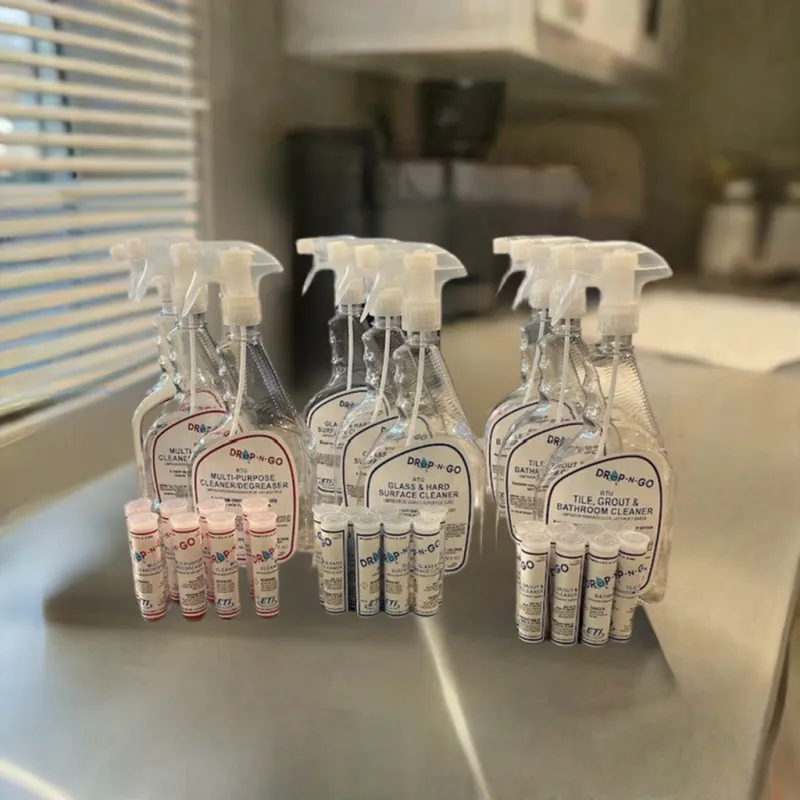

Commercial-Grade Products vs. Dollar Store Alternatives

One of the key distinctions Kemper emphasizes is the difference between commercial-grade cleaning products and those found at discount retailers like dollar stores. While dollar store products may seem cost-effective, they often lack the potency and reliability of commercial-grade alternatives. Commercial products are formulated with higher concentrations of active ingredients, such as surfactants or disinfectants, and are designed for heavy-duty use in large-scale environments like offices, warehouses, or healthcare facilities.

For example, a commercial-grade floor cleaner might contain a balanced blend of surfactants and emulsifiers that effectively removes dirt and grime from high-traffic areas, while a dollar store equivalent might require multiple applications to achieve similar results. Additionally, commercial products often come with detailed instructions for dilution and application, ensuring consistent performance. By investing in high-quality products, companies can reduce labor costs, minimize product waste, and achieve better cleaning outcomes.

Dilutions and the pH Scale

Proper dilution is a cornerstone of effective cleaning. Many cleaning products are sold as concentrates, requiring dilution with water to achieve the desired strength. Incorrect dilution can lead to ineffective cleaning or damage to surfaces. For instance, over-concentrated solutions can leave residues that attract dirt, while under-concentrated solutions may fail to remove soils.

The pH scale also plays a critical role in dilution. Some cleaning products, particularly those that are highly acidic or alkaline, must be diluted to a safe pH level to avoid damaging surfaces or posing risks to workers. For example, a concentrated alkaline degreaser might have a pH of 13, but when diluted properly, it may drop to a safer pH of 10, making it suitable for use on floors without risking damage to the finish.

Companies can benefit from training their cleaning staff on proper dilution techniques and pH testing. Simple tools like pH test strips can help ensure that solutions are mixed correctly, enhancing both safety and efficacy. This knowledge is particularly important in industries like healthcare, where improper cleaning can lead to cross-contamination or health risks.

Common Housekeeping Challenges

Kemper’s guideline highlights several common housekeeping challenges that companies face and how chemistry can help address them. These include mold, floors, odors, glass, and blood.

Mold and Mildew

Mold and mildew, including pink, green, and black varieties, are common issues in corporate environments, particularly in restrooms, kitchens, or areas with poor ventilation. Mold thrives in damp, humid conditions, and its removal requires both chemical and mechanical action. Bleach-based cleaners, which are mildly alkaline, are effective at killing mold spores, but they must be used with caution to avoid damaging surfaces or creating harmful fumes.

Preventing mold growth involves controlling moisture levels and using cleaning products with antifungal properties. For example, quaternary ammonium compounds (quats) are commonly used in disinfectants to prevent mold and mildew in high-risk areas. Companies can also invest in dehumidifiers or improved ventilation systems to complement their cleaning efforts.

Floors

Floors in corporate settings, whether carpeted, tiled, or hardwood, are subject to heavy wear and tear. Different floor types require specific cleaning approaches. For instance, acidic cleaners are ideal for removing mineral deposits from tile floors, while neutral pH cleaners are better suited for polished hardwood to avoid stripping the finish. Understanding the chemistry of floor cleaners allows companies to maintain their flooring investments and create a professional, welcoming environment.

Odors

Odors are a common complaint in corporate spaces, particularly in restrooms, break rooms, or areas with heavy foot traffic. Odor control often involves neutralizing or masking unpleasant smells. Chemical deodorizers, such as those containing enzymes or oxidizing agents, break down odor-causing molecules, while air fresheners may simply mask smells. By understanding the source of odors (e.g., bacterial growth or organic matter), companies can select the most effective products, such as enzyme-based cleaners for organic odors or activated charcoal for chemical smells.

Glass

Achieving streak-free glass is a challenge in corporate offices with large windows or glass partitions. Ammonia-based cleaners, which are mildly alkaline, are commonly used for glass because they effectively cut through grease and grime. However, overuse can lead to streaks or damage to tinted windows. Understanding the chemistry of glass cleaners helps companies avoid common pitfalls and maintain a polished appearance.

Blood and Biohazards

In healthcare facilities or workplaces where accidents may occur, cleaning blood and other biohazards requires specialized products and procedures. Disinfectants with high antimicrobial activity, such as those containing hydrogen peroxide or quats, are essential for safely removing blood while preventing the spread of pathogens. Proper training in handling biohazards, combined with an understanding of disinfectant chemistry, ensures compliance with health and safety regulations.

Implementing a Chemistry-Based Cleaning Strategy

To fully leverage the art of cleaning, companies should adopt a chemistry-based approach to their housekeeping practices. This involves several key steps:

Training Staff: Educate cleaning staff on the chemistry of cleaning products, including surfactants, pH, and dilution ratios. Training should also cover the five cleaning factors and how to apply them in different scenarios.

Selecting Quality Products: Invest in commercial-grade cleaning products that are tailored to the specific needs of the facility. Avoid relying on low-cost alternatives that may compromise results.

Customizing Cleaning Plans: Develop cleaning protocols that account for the unique challenges of the workplace, such as high-traffic areas, sensitive surfaces, or biohazard risks. Use the pH scale and cleaning factors to guide product selection.

Monitoring and Maintenance: Regularly assess the effectiveness of cleaning practices through inspections and feedback. Use tools like pH meters or test strips to ensure proper dilution and application.

Sustainability Considerations: Choose eco-friendly cleaning products with biodegradable surfactants or low-VOC (volatile organic compound) formulas to reduce environmental impact while maintaining efficacy.

The Benefits of a Chemistry-Driven Approach

By embracing the chemistry behind cleaning, companies can achieve numerous benefits:

Improved Efficiency: Properly selected and applied cleaning products reduce the time and labor required for cleaning tasks, allowing staff to focus on other priorities.

Cost Savings: Using the right products at the correct dilution ratios minimizes waste and extends the lifespan of cleaning supplies and facility surfaces.

Enhanced Safety: Understanding pH and chemical interactions reduces the risk of accidents, such as chemical burns or damage to surfaces, and ensures compliance with safety regulations.

Better Workplace Environment: Clean, odor-free, and well-maintained facilities create a positive impression for employees, clients, and visitors, boosting morale and productivity.

Sustainability: A chemistry-based approach enables companies to choose environmentally friendly products, aligning with corporate sustainability goals.

Conclusion

The art of cleaning is far more than a routine task—it’s a science that, when understood and applied correctly, can transform corporate housekeeping practices. By leveraging insights from Sean Kemper’s "The Art of Cleaning," companies can make informed decisions about cleaning products, techniques, and protocols. From understanding the role of surfactants and emulsifiers to mastering the five cleaning factors and addressing common challenges like mold and odors, a chemistry-driven approach empowers businesses to achieve cleaner, safer, and more efficient workplaces. As companies continue to prioritize health, safety, and sustainability, the art of cleaning will remain a critical tool for success.